tube amplifiers

Trimax, Centre Industries

Trimax A54 aka Type3 Amplifier

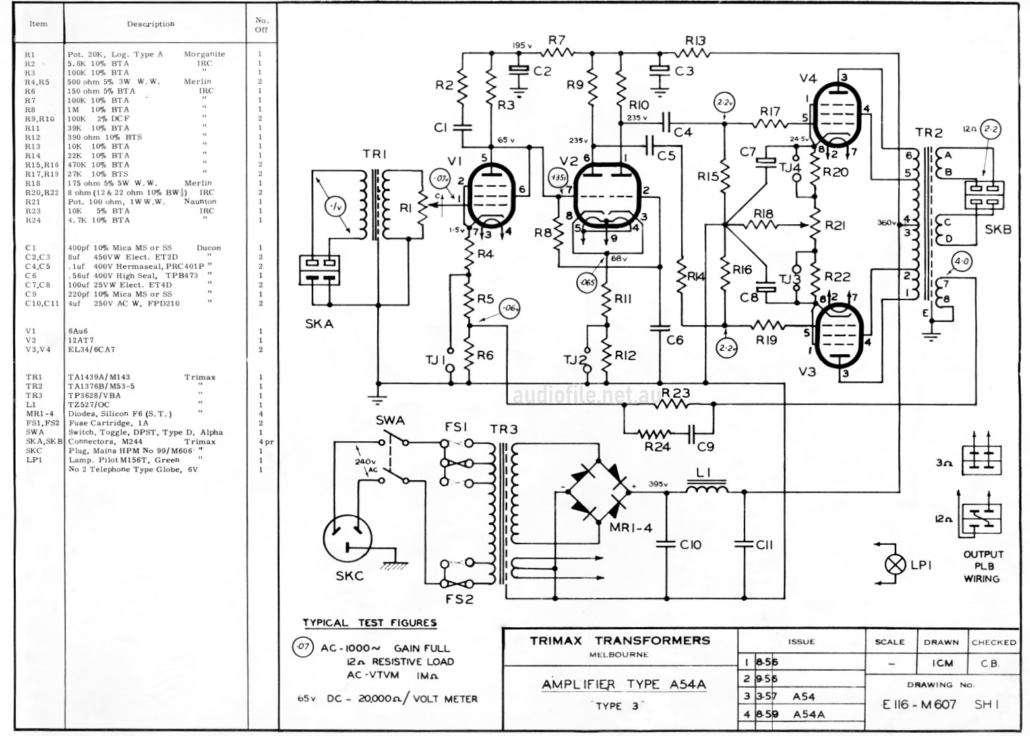

Australian designed and built monitoring power amplifier (tube rectifier)

*The original

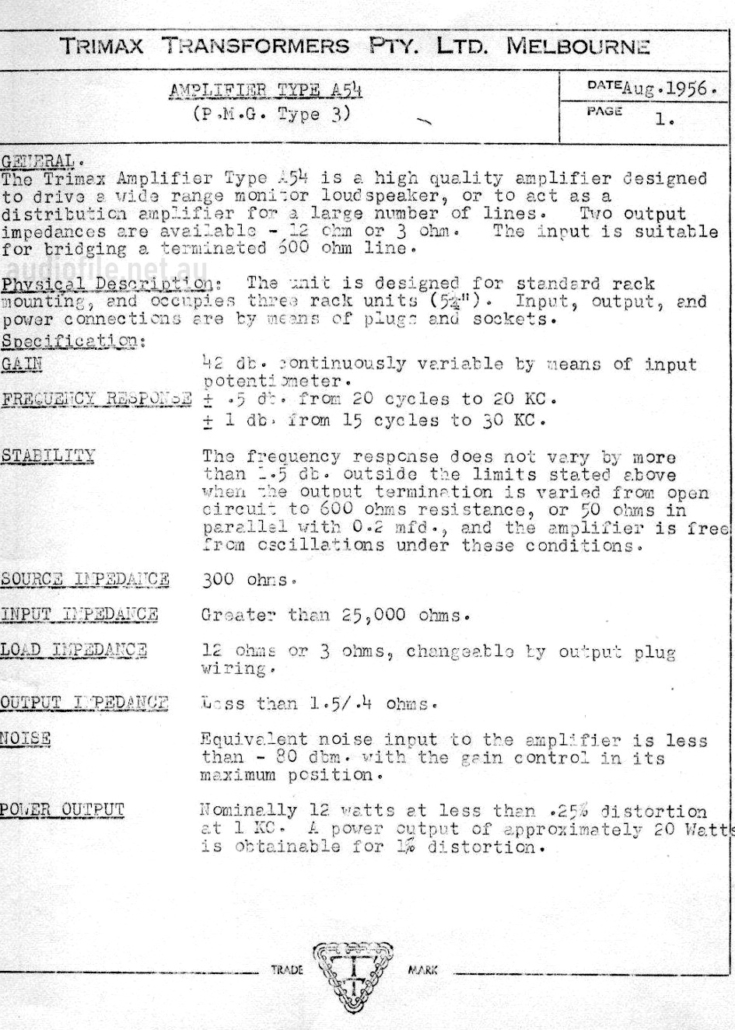

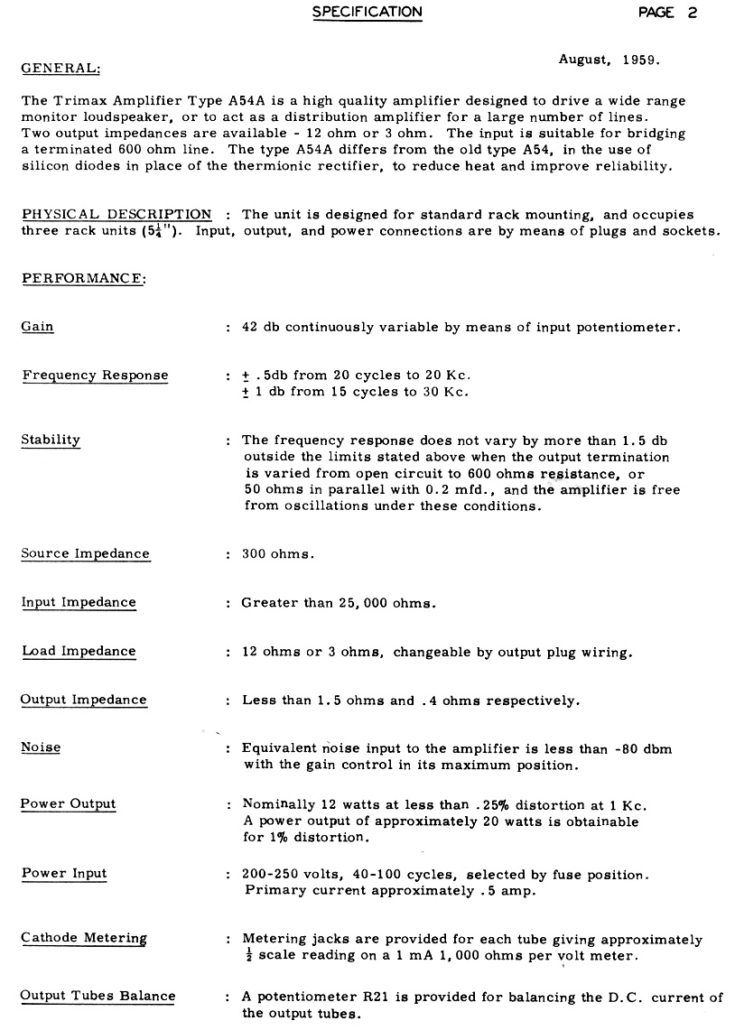

Specifications

Description

The Trimax A54, aka the Type 3 amplifier, was designed and produced in Melbourne by the Trimax Transformer Company

The amplifier was produced in accordance with the Post Master General (PMG) requirements for an audio monitoring amplifier, the so called Type 3 amplifier

The timing of the A54’s introduction in 1956 coincided with an Australian Broadcasting Corporation (ABC) contract to provide a Type 3 power amplifier able to be used in a broadcast setting during the forthcoming Melbourne Olympic Games

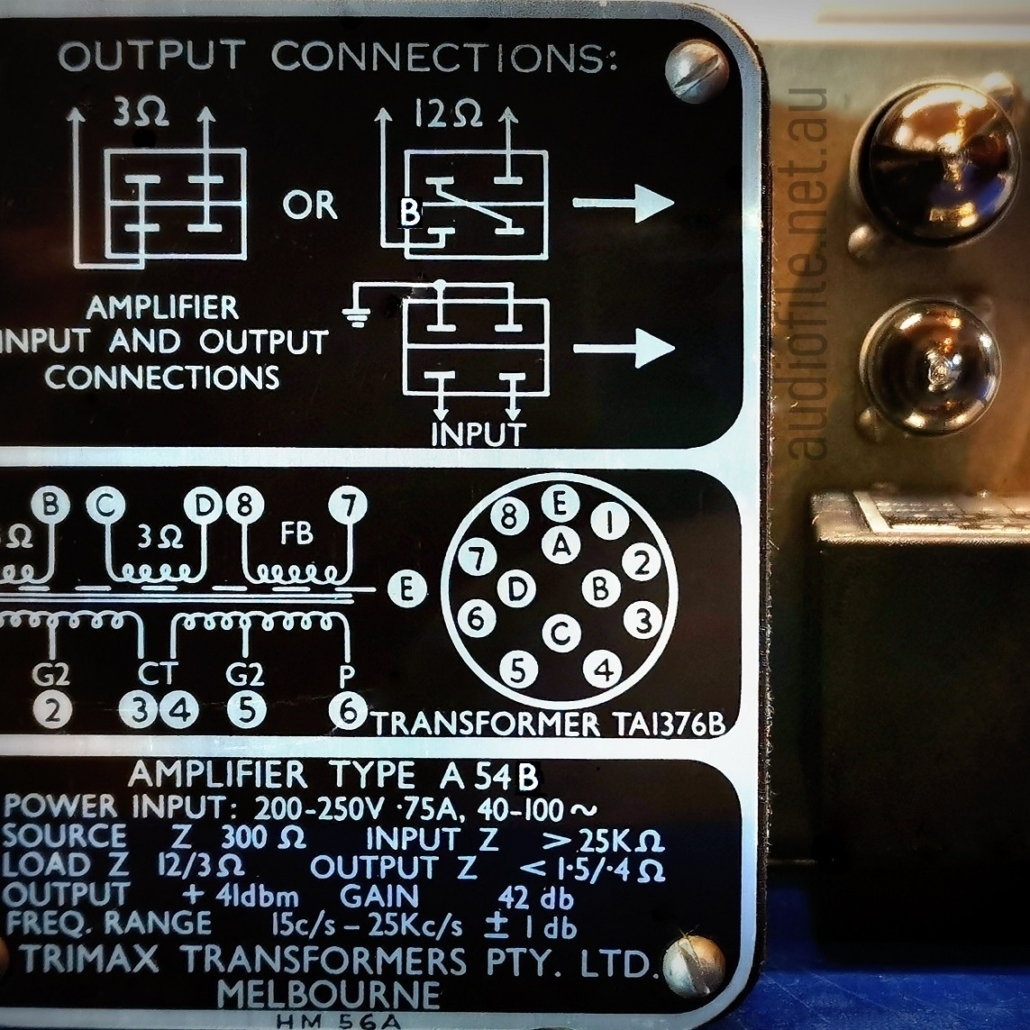

The A54 is capable of delivering up to 20W of undistorted, high fidelity audio program to a wide-range speaker system and could also be used as a distribution amplifier

Frequency response is claimed to be an impressive, for 1956, 20Hz to 20kHz +/-0.5dB although the power level is not stated

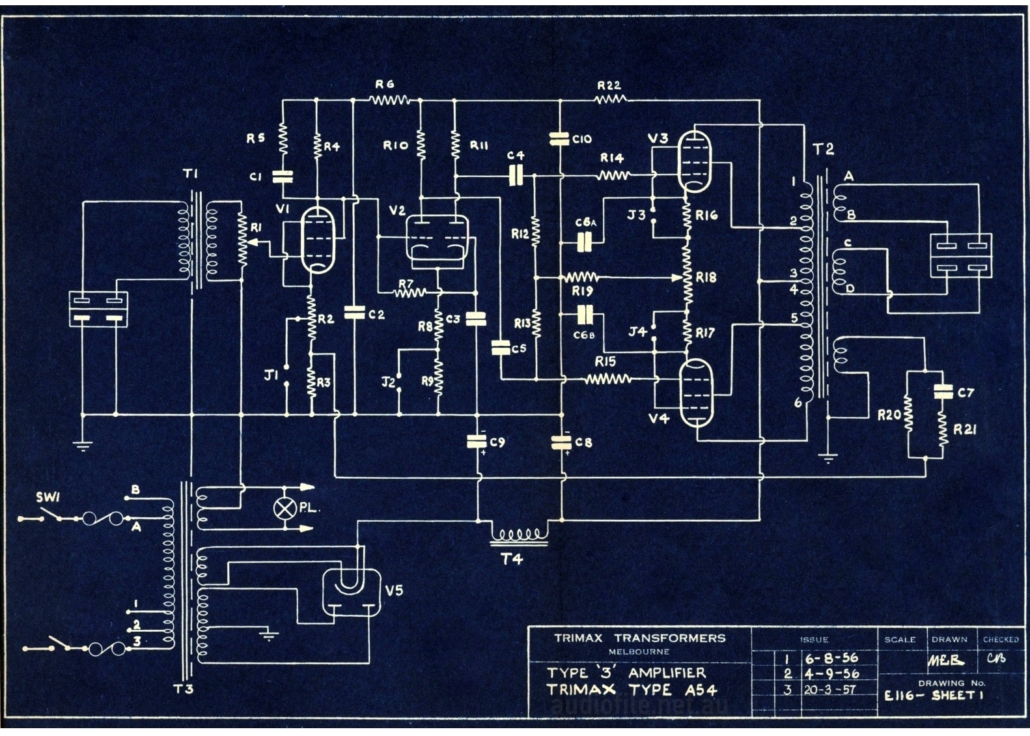

The design is based on the well known and imitated Mullard 5-20 circuit first published in the same year that took advantage of new developments in output tubes and transformers to implement an ultra-linear output configuration for lower distortion at a higher output power than was previously possible

The output tubes were the newly developed EL34 pentode used with a relatively low nominal supply voltage of 360V. The long tailed pair phase-splitter was constructed around the medium mu 12AT7 dual triode with a triode strapped 6AU6 used as the input amplifier stage.

The power supply consisted of a 5V4 full wave rectifier with C-L-C filter, the primary filter capacitors being paper-in-oil types. Resistors were mostly carbon composition types or wire-wound for power use and the coupling capacitors were either paper-in-oil or waxed paper types

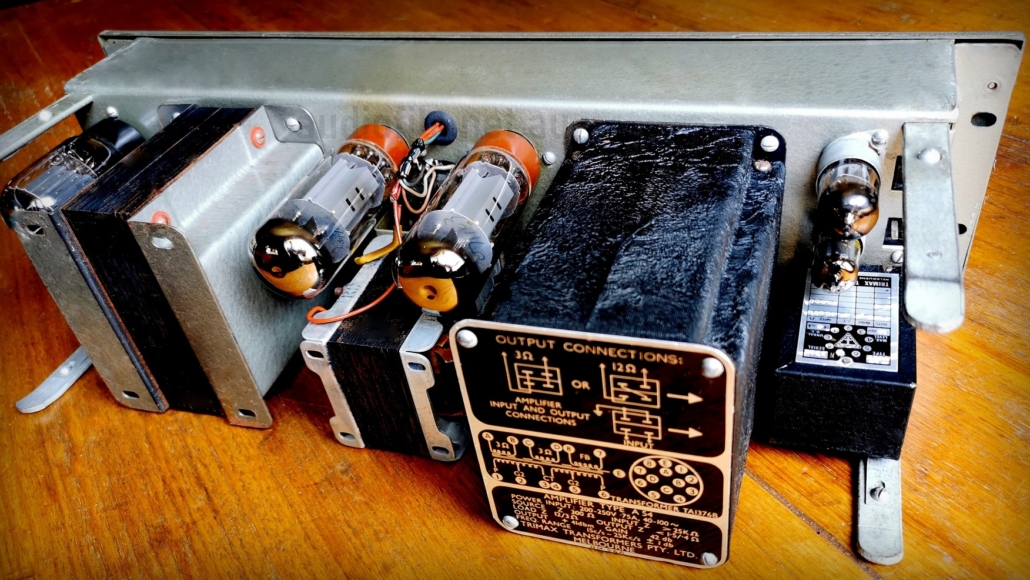

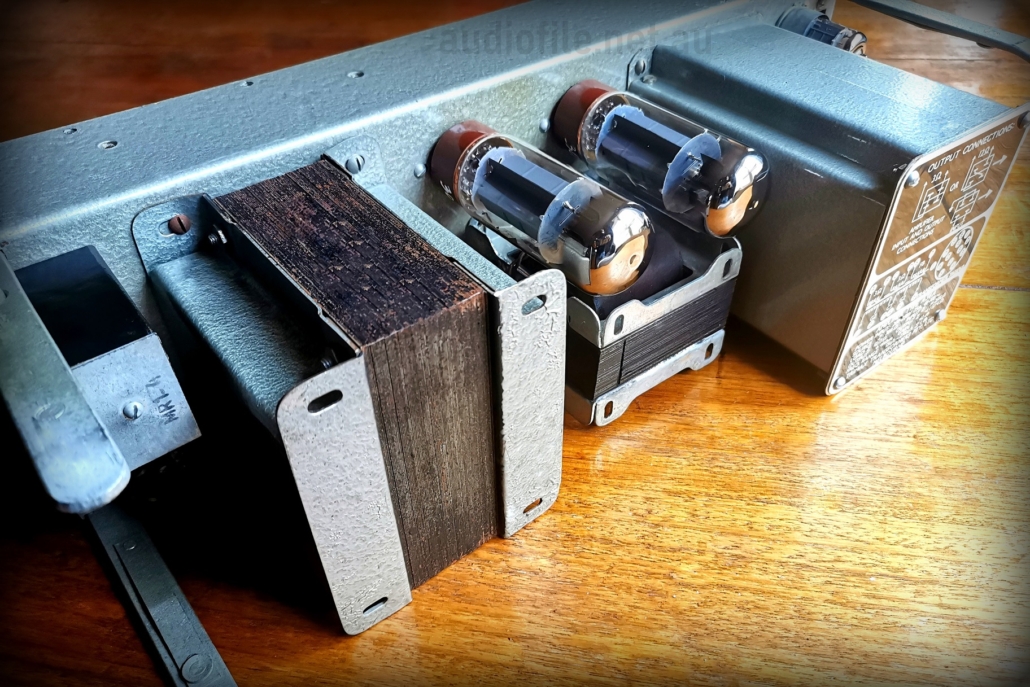

While both the power and output transformers were conventional laminated E-I core types, both featured a electrostatic screen between winding for lowest leakage inductance. Judging by the relatively huge size and mass of the output transformer it must have considerable primary inductance allowing the amplifier to drive full power at the lowest frequencies without distortion

The output transformer also features a tertiary feedback winding optimised for purpose and has dual secondaries rated at 6 ohms each useable in series for nominal loads of 12ohms or in parallel for 3ohm loads. The output transformer also appears to be potted to help prevent moisture ingress. Because of the high specification of the output transformer a relatively large amount of feedback can be employed to minimise disortion, approximately 30dB

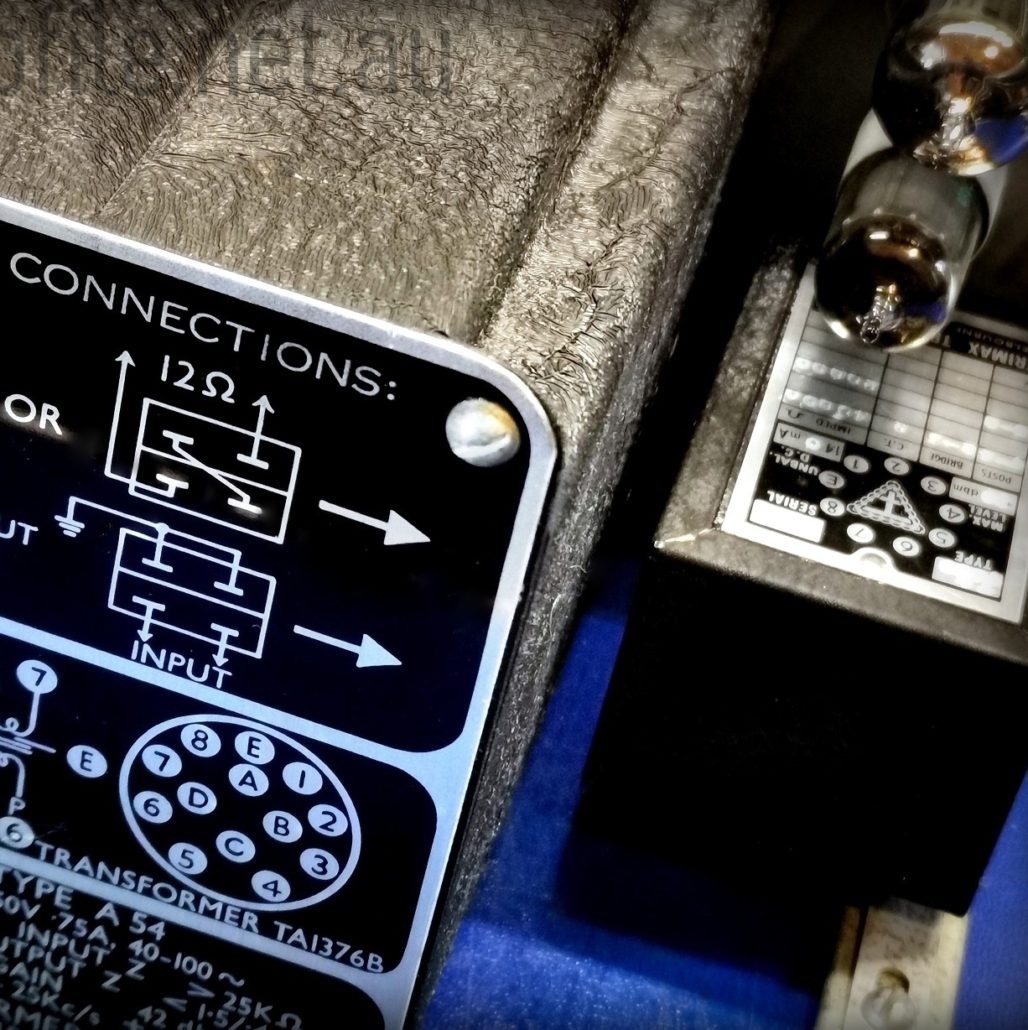

An input transformer is used that can bridge a 600ohm line with an input impedance of approximately 20kohms. An input potentoimeter allows the gain of the amplifier to be adjusted to a maximum of 42dB. The input and output connectors are an unusual design being manufactured by Trimax and not compatible with an other known type. All of the transformers were manufactured by Trimax and the other components all seem to be of Australian manufacture as well!

The A54 is housed in a 19″ 3RU enclosure and with all of the tubes and transformers on the rear of the enclosure and all of the passive components housed internally behind an easily removable front panel. An aperture in the front panel allows access to cathode resistor monitoring points for each tube to check for correct operation and to allow adjustment of output tube balance via a wire-wound potentiometer

A heavily perforated steel cover slides on the rear of the enclosure over projecting tongues to protect the tubes

In use when mounted in a rack, the heat from the output tubes can readily escape but care was needed when stacking amplifiers as was common in multi-amplifier installations as the smoothing choke from the amp above is directly above the lower amplifiers output tubes, at least a couple of rack units space would have been required to prevent cooking the choke!

Restoration

- Trimax A54 Restoration – Coming Soon

Trimax A54a aka Type3 Amplifier

Australian designed and built monitoring power amplifier (silicon rectifier)

* No you’re not seeing double

Specifications

Description

By 1959 silicon diodes were available capable of handling the voltages and currents required for duty in audio power amplifier power supplies. The description of the Trimax A54a is identical to the A54 already discussed with one key difference, the use of the newly developed silicon rectifiers in the ‘A’ model replacing the vacuum tube rectifier of the original

The silicon full bridge is housed in a small phenolic box in the place where the 5V4 stood, it can be seen at the far left of the picture below

Visually, apart from the rectifier box, the A54a has the input and output transformers painted grey rather than black

The schematic shows the 5V4 tube rectifier replaced with a full bridge silicon rectifier. The power transformer output voltage is adjusted to maintain the nominal 360V power supply for the output stage.

The move to a the new rectifier improves voltage regulation and tightens the bass when driven hard. The higher efficiency of the new rectifier also gives the power transformer an easier time

A few other minor component value changes were made but otherwise the design, construction and performance of the amplifier is identical

Restoration

- Trimax A54a Restoration – Coming Soon

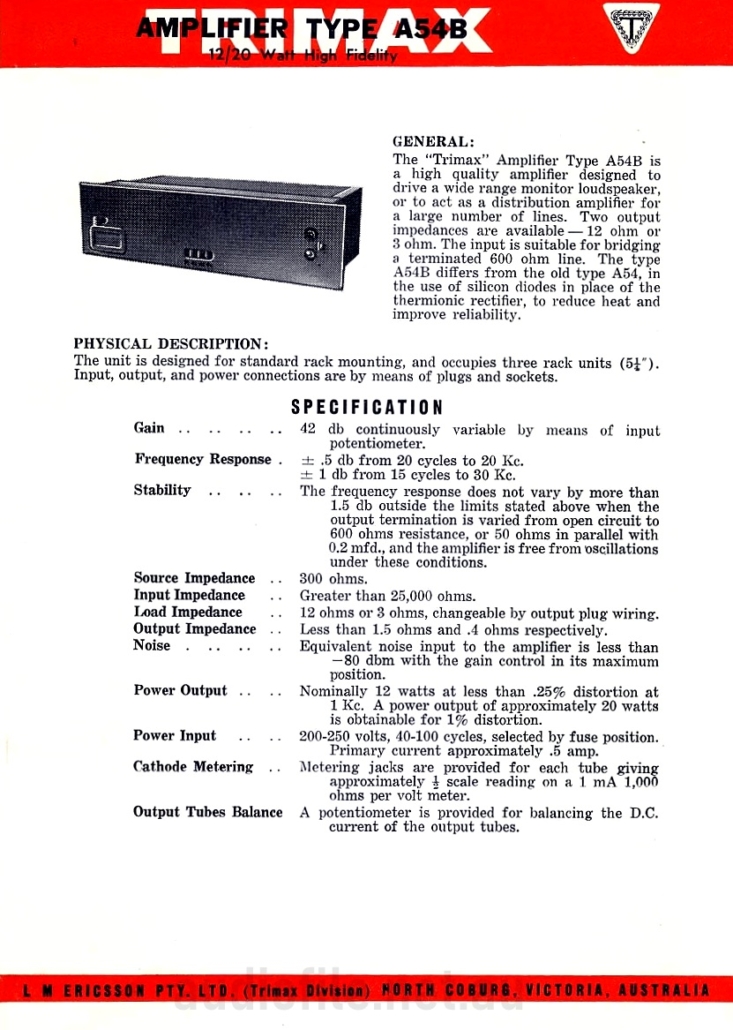

Trimax A54B aka Type3 Amplifier

Australian designed and built monitoring power amplifier (silicon rectifier)

* Update to the Trimax A54a

Specifications

With thanks to Peter o’Neil of www.oneillassociates.com.au

Description

In 1961 Swedish owned L.M. Ericsson gained a controlling interest in Trimax Transformers and this presaged an update to the A54a, the logically named if somewhat uninspiring A54B.

Changes were minor but included a new front panel design that featured a pair of quick release 1/4 turn fasteners in place of the four corner fasteners of the earlier designs that were always getting lost.

This front design was also used by Centre Industries in their clone of the A54

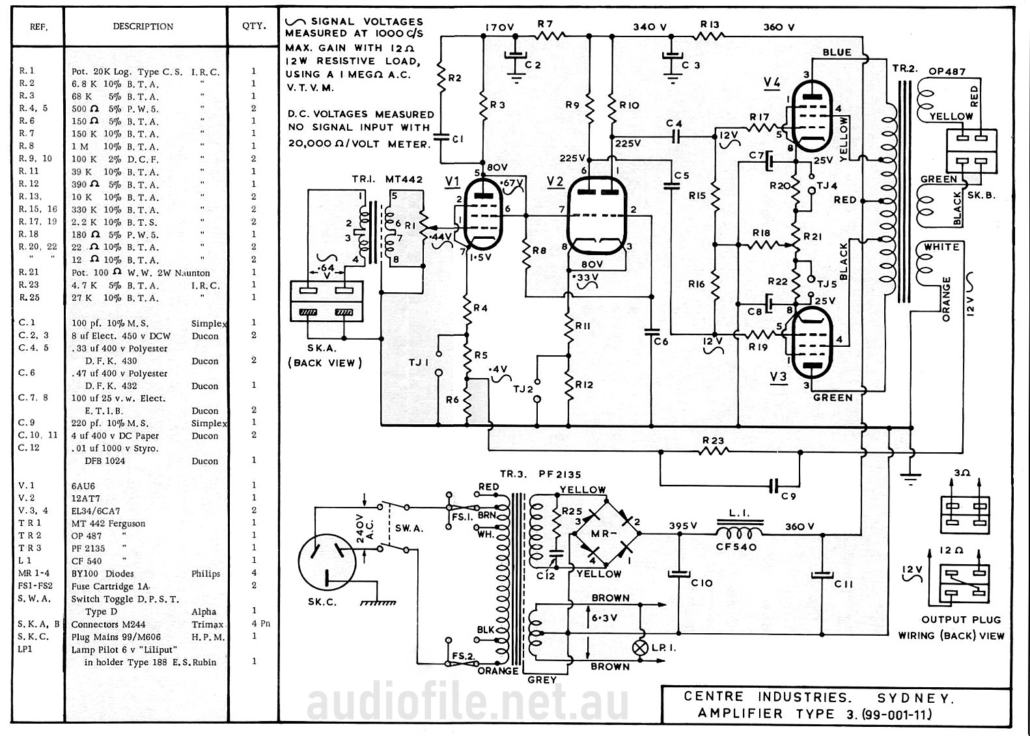

Centre Industries Type3 Amplifier

Australian designed and built monitoring power amplifier (silicon rectifier)

* Centre Industries of Sydney clone of the Trimax A54a

Specifications

Description

Following the success of the Trimax A54, A54a & A54B Centre Industries in Sydney also made a version of the Type 3 amplifier to the same PMG specification

But rather than using transformers from the Melbourne based Trimax Transformer company instead sourced iron from Ferguson Transformers in Sydney

Another example of the Melbourne-Sydney rivalry?

It’s not certain exactly when the Centre Industries Type 3 was first introduced but was after the A54B from 1961 and this particular example dates from 1964

Otherwise the design is basically the same as the Trimax A54a already discussed

The input stage runs a slightly higher anode voltage and lower gain, but the phase-splitter value has the same operating point as the Trimax A54. The output stage grid stopper resistors are an order of magnitude smaller in value and the grid resistors slightly smaller so the phase-splitter would be working quite a bit harder driving the output tubes

Owing to the different output transformer with its peculiar parasitics, the feedback network is slightly different to help stabilse the amplifier. The output transformer has a lower turns ratio to the feedback winding and combined with a lower value series feedback resistor results in the same overall feedback of around 30dB

Other minor circuit changes from the Trimax design include an R-C snubber across the power transformer secondary to reduce diode commutation noise

While being housed in the same type of 19″ 3RU enclosure, the component layout is different with the internal passive components being laid out along two strip boards running the length of the chassis and including the rectifier diodes

Frequency response of the Centre Industries Type3 is quoted as being 30Hz to 15kHz +/-0.5dB slightly less than the Trimax A54, but again the power level used for the test isn’t stated